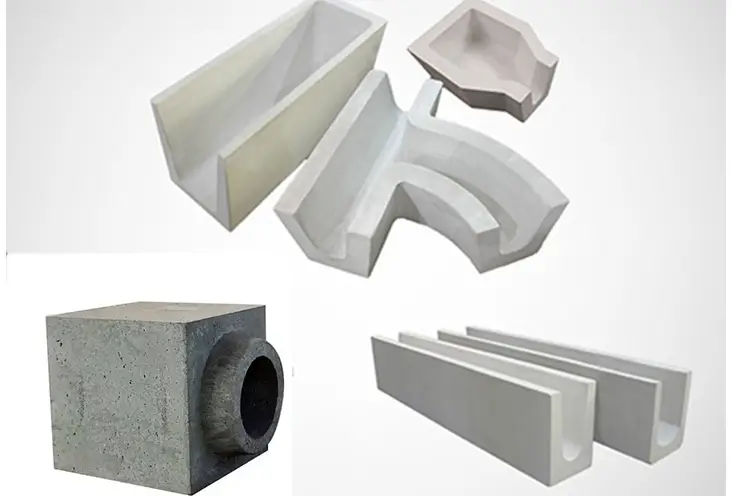

Refractory Precast Shapes are high-precision, ready-to-install refractory components designed for industrial furnaces and kilns, ensuring superior thermal stability, durability, and reduced installation time.

Chat on WhatsApp:

+8615038278221Email Us:

info@rsrefractories.com

Refractory Precast Shapes are engineered monolithic or modular refractory components manufactured from high-quality refractory castables, alumina, or magnesia materials. Precast shapes include arches, channels, blocks, and specialty linings, designed to meet specific furnace geometries and operating conditions.

Using precast shapes ensures consistent quality, faster installation, lower labor costs, and enhanced lining integrity compared to traditional brickwork. They withstand high temperatures, thermal shock, mechanical stress, and chemical attack, making them ideal for continuous industrial operations.

Custom sizes and materials are available to match steel, non-ferrous, cement, and petrochemical industries, with a typical service life up to 10–15 years depending on operating conditions.

Key Advantages:

High-temperature resistance up to 1750°C

Excellent thermal shock stability

Precision-engineered for seamless assembly

Reduced downtime and maintenance costs

Customizable shapes and materials

|

Item |

GCJ-70 |

GCJ-65 |

GCJ-55 |

|

|

Al2O3 |

≥% |

70 |

65 |

55 |

|

SiC |

% |

10-15 |

10-15 |

10-15 |

|

F·C |

% |

2-6 |

2-6 |

2-6 |

|

Bulk Density ≥g/㎝3 |

110℃×24 |

2.85 |

2.75 |

2.65 |

|

1450℃×3 |

2.80 |

2.70 |

2.60 |

|

|

CCP, ≥MPa |

110℃×24 |

20 |

20 |

15 |

|

1350℃×3 |

80 |

60 |

40 |

|

|

CMOR ≥MPa |

110℃×24 |

6 |

4 |

4 |

|

1350℃×3 |

12 |

10 |

6 |

|

|

1500℃×3 |

0-0.5 |

0-0.5 |

0-0.5 |

|

Comprehensive Refractory Product Range

We manufacture 3 main types of refractory materials — refractory castables, high alumina cement, and refractory bricks — covering 100+ industrial furnace types worldwide.

Certified Quality and International Standards Compliance

All batches undergo strict quality control. Products comply with ISO, ASTM, and GB standards, ensuring reliable performance in high-temperature industrial applications.

Annual Production Capacity of 130,000 Tons

With a large-scale capacity of 130,000 tons per year, we guarantee stable supply and on-time delivery for long-term and large-volume projects.

Exported to 120+ Countries and 1,000+ Projects

Our products have been successfully delivered to over 120 countries, supporting more than 1,000 industrial projects, including cement, steel, incineration, glass, and petrochemical furnaces.

20+ Years of Experience in Refractory Manufacturing

With over 20 years of experience, we understand real furnace conditions and deliver materials proven in long-term industrial operations worldwide.

Professional Technical Support and Free Samples

We provide technical assistance from material selection to installation guidance, with free samples available for testing and supporting 1,000+ projects globally.

Fill out the form to request a free, detailed quote.