Silicon Carbide Based Monolithic Refractories

Silicon Carbide Based Monolithic Refractories include Silicon Carbide Castable, Silicon Carbide Ramming Mix,Silicon Carbide Refractory Mortar,Refractory Mortar For Composite Bricks.Alumina-silica Monolithic refractories

Alumina-silica monolithic refractories include dry impermeable castable, high-strength castable,lightweight castable, Insulation refractory mortar.Low Cement Castable

Using high-quality bauxite and flint clay as the main raw material and calcium aluminate cement as the binder, this castable has the characteristics of high strength and stable performance.Non-stick Alumina Castable

This castable is made of super-grade alumina as the main raw material, and pure calcium aluminosilicate cement is used as the binder. By adding anti-wetting agent and optimizing the matrix composition structure, it has good resistance to aluminum liquid infiltration.High Alumina Plastic Refractory

This product is made of high-quality bauxite as the main raw material and phosphate as the binder. It has the characteristics of long shelf life, good thermal shock resistance, and good construction performance.Light Weight Insulating Castable

The castable is made of mullite lightweight aggregate, floating beads as main raw materials, and aluminate cement is used as the binder. It has the characteristics of good thermal conductivity, high strength and so on. It is widely used for heat insulation of kilns.

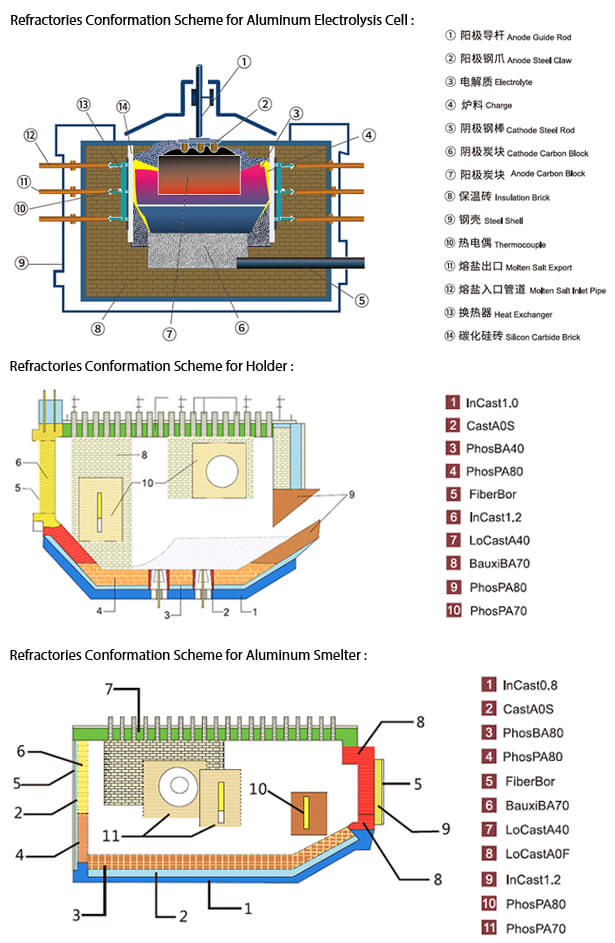

Bricks for Aluminum Electrolysis Cell(side wall bricks, corner bricks

and composite bricks)

Not only made of high-quality silicon carbide and industrial silicon powder

as raw materials, but also made by vibrating pressure forming and stepped

high pressure oxidation process, this product is characterized with good

cryolite corrosion resistance, strong oxidation resistance, high temperature

strength, strong thermal conductivity and long service life , so it is

an ideal material for the side wall of a 180KVA large-scale pre-baked electrolytic

cell. Compared with carbon blocks, this product improves current efficiency,

reduces DC power consumption, and has a significant effect of energy saving

and consumption reduction

Silicon Nitride Bonded Silicon Carbide Port Bricks :

This brick has the characteristics of high temperature resistance, corrosion and erosion resistance of molten aluminum (aluminum alloy), no pollution of molten aluminum (aluminum alloy), and good thermal shock resistance. It is mainly used in the casting process of aluminum (aluminum alloy) melting and refining.

Direct-bonded magnesia chrome bricks are made of high-purity or sub-high-purity sintered or fused magnesia and chromium concentrate as raw materials. The product has few impurities. After being fired at high or ultra-high temperature, the glass phase is concentrated in the triangular area of the crystal phase, and the crystal phase and the crystal phase are directly combined. It has the characteristics of low porosity, high crushing strength, strong wear resistance, corrosion resistance, thermal shock resistance and good peeling resistance.

| Brand Item | Direct-bonded Magnesia-Chrome Brick | ||||||||||

| RSM Ge-8A | RSM Ge-8B | RSM Ge-12A | RSM Ge-12B | RSM Ge-16A | RSM Ge-16B | RSM Ge-18A | RSM Ge-18B | RSM Ge-20 | RSM Ge-22 | RSM Ge-26 | |

| MgO , % ≥ | 82 | 76 | 75 | 70 | 70 | 65 | 65 | 62 | 65 | 60 | 55 |

| Cr 2 O 3 , % ≥ | 8 | 8 | 12 | 12 | 16 | 16 | 18 | 18 | 20 | 22 | 26 |

| SiO 2 ,% ≤ | 1.5 | 2.5 | 1.5 | 2.5 | 1.5 | 2.5 | 1.5 | 2.5 | 2.0 | 2.0 | 2.0 |

| Apparent Porosity,% ≤ | 17 | 18 | 17 | 18 | 17 | 18 | 17 | 18 | 19 | 19 | 20 |

| CCS , MPa ≥ | 45 | 45 | 45 | 45 | 45 | 40 | 45 | 40 | 40 | 40 | 40 |

| 0.2MPa Refractoriness Under Load ,℃ ≥ | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1700 | 1700 |

| (1400℃) Thermal Expansion Rate, % | 1.5 | -- | - | -- | 1.6 | -- | -- | - | -- | -- | 1.8 |

| Brand Item | Magnesia Chrome Brick | |||

| RSMGe-8 | RSMGe-12 | RSMGe-16 | RSMGe-20 | |

| MgO , % ≥ | 60 | 55 | 45 | 40 |

| Cr 2 O 3 , % ≥ | 8 | 12 | 16 | 20 |

| Apparent Porosity ,% ≤ | 21 | 21 | 22 | 22 |

| CCS , MPa ≥ | 30 | 30 | 25 | 25 |

| 0.2MPa Refractoriness Under Load, ℃ ≥ | 1530 | 1550 | 1550 | 1550 |

Semi-rebonded magnesia chrome bricks are made of fused magnesia chromium particles, high-purity fused or sintered magnesia and chromium concentrate as raw materials, fired at ultra-high temperature. Not only thermal shock resistance is good as direct-bonded magnesia chrome bricks, but also corrosion resistance is good as fused rebonded magnesia chrome bricks.

| Brand Item | Semi-rebonded Magnesia Chrome Brick | ||||||||||||

| RS RMGe -12A | RS RMGe -12B | RS RMGe -14A | RS RMGe -14B | RS RMGe -16A | RS RMGe -16B | RS RMGe -18A | RS RMGe -18B | RS RMGe -20A | RS RMGe -20B | RS RM Ge-22 | RS RM Ge-26 | RS RM Ge-30 | |

| MgO , % ≥ | 78 | 75 | 75 | 72 | 72 | 70 | 70 | 68 | 68 | 65 | 65 | 60 | 55 |

| Cr 2 O 3 , % ≥ | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 26 | 30 |

| SiO 2 , % ≤ | 1.5 | 2.0 | 1.5 | 2.0 | 1.5 | 2.0 | 1.5 | 2.0 | 1.5 | 2.0 | 2.0 | 2.0 | 2.0 |

| Apparent Porosity, % ≤ | 15 | 16 | 15 | 16 | 15 | 16 | 15 | 16 | 15 | 16 | 16 | 16 | 16 |

| CCS, MPa ≥ | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 45 | 45 |

| 0.2MPa Refractoriness Under Load , ℃ ≥ | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1700 | 1700 |

| (1400℃) Thermal Expansion Rate, % | 1.4 | -- | --- | --- | 1.5 | -- | -- | -- | 1.6 | -- | -- | 1.7 | -- |

Fused rebonded magnesia chrome bricks are re-sintered products made of fused magnesia chrome particles.

Magnesium-aluminum-chromium composite spinel brick is a new type of high-grade composite material, which developed by Rongsheng according to the characteristics of zinc volatilization kiln. It not only has excellent scouring and erosion resistance, but also has good peeling resistance. After being used by Zhuzhou Smelting Co., Ltd., Yunnan Copper Zinc Co., Ltd. and other large zinc smelting enterprises, this kind of brick has obvious advantages over chrome slag bricks, direct-bonded magnesia chrome bricks, magnesia bricks and thermal shock resistant high alumina bricks. It is the ideal material for zinc volatilization kilns.

| Brand Item | Fused Rebonded Magnesia Chrome Brick | Magnesium-aluminum-chromium Composite Spinel Brick | ||||||||

| RSRM Ge-12 | RSRM Ge-14 | RSRM Ge-16 | RSRM Ge-18 | RSRM Ge-20 | RSRM Ge-22 | RSRM Ge-26 | RSRM Ge-30 | RSMAC -A | RSMAC -B | |

| MgO , % ≥ | 78 | 75 | 72 | 70 | 68 | 65 | 60 | 55 | 80 | 75 |

| Cr 2 O 3 ,% ≥ | 12 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | 3-5 | 3-5 |

| SiO 2 , % ≤ | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.0 | 2.0 | 2.0 | Al2O3 6 | |

| Apparent Porosity , % ≤ | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 17 | 18 |

| CCS, MPa ≥ | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 50 | 50 |

| 0.2MPa Refractoriness Under Load , ℃ ≥ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1650 |

| Thermal Shock Resistance ≥ | -- | -- | -- | -- | -- | -- | -- | -- | 100 | 80 |

| Thermal Expansion Rate, % | --- | -- | 1.5 | -- | -- | -- | -- | 1.7 | -- | -- |

| Brand Item | High Alumina Bricks | Phosphate Bonding High Alumina Bricks | Fire Clay Bricks | ||||||||

| RSLZ-75 | RSLZ-65 | RSLZ-55 | RSLZ-48 | PA | RSGH-80 | RSN -1 | RSN -2a | RSN -2b | RSN -3a | RSN -3b | |

| Al 2 O 3 , % ≥ | 75 | 65 | 55 | 48 | 77 | 80 | -- | -- | -- | -- | -- |

| Fe 2 O 3 , % ≤ | 3.2 | 2.0 | -- | -- | -- | -- | -- | ||||

| Apparent Porosity , % ≤ | 23 | 23 | 22 | 22 | -- | -- | 22 | 24 | 26 | 24 | 26 |

| Bulk Density ,g/cm 3 ≥ | -- | -- | -- | -- | 2.7 | 2.9 | -- | -- | -- | -- | -- |

| CCS, MPa ≥ | -- | -- | -- | -- | 65 | 60 | 60 | 25 | 20 | 20 | 15 |

| Refractoriness Under Load ≥ | 1500 | 1450 | 1420 | 1400 | 1250 | 1460 | 1400 | 1350 | -- | 1320 | -- |

| 1400℃×2h Reheating Linear Change Rate, % | 1500℃×2h +0.1~-0.4 | 1500℃×2h +0.1~-0.4 | 1450℃×2h +0.1~-0.4 | -- | -- | -- | +0.1 ~-0.4 | +0.1 ~-0.5 | +0.2 ~-0.5 | 1350℃×2h +0.2~-0.5 | -- |

| Refractoriness,℃ ≥ | 1790 | 1790 | 1770 | 1770 | 1780 | 1790 | 1760 | 1740 | 1740 | 1720 | 1720 |