1. Top Chinese Manufacturer and Exporter

2. High quality and competitive price

3. Contact us to get free spec and price list

No matter where you buy from, understanding our prices first is the most correct choice

Whatsapp:

8615038278221E-mail:

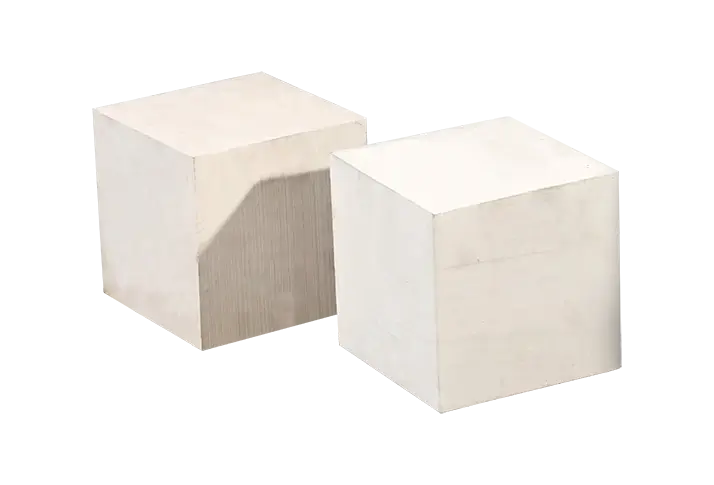

info@rsrefractories.comMullite Bricks are an excellent quality high alumina refractory product with about 65~75 percent alumina content. Mullite brick is made of mullite as the main raw material and molded through high temperature firing and pressure. Mullite bricks have advantage performance on furnace and kiln application such as high temperature resistance, chemical and mechanical corrosion, good thermal shock resistance and so on.

| Items | MU 65 | MU 70 | MU 75 | |

| Chemical Composition | Al2O3 % | ≥65 | ≥70 | ≥75 |

| SiO2 % | ≤33 | ≤26 | ≤24 | |

| Fe2O3 % | ≤1.0 | ≤0.6 | ≤0.4 | |

| Bulk Density g/cm3 | ≥2.55 | ≥2.55 | ≥2.55 | |

| Reheating Linear Change (%) 1500℃×2h | 0~+0.4 | 0~+0.4 | 0~+0.4 | |

| Apparent Porosity % | ≤17 | ≤17 | ≤18 | |

| Thermal Conductivity W/(m·K) 1000℃ | 1.84 | 1.95 | 1.95 | |

| Cold Crushing Strength MPa | ≥60 | ≥80 | ≥80 | |

| Thermal Expansion Coefficient (×10-6℃-1) | 0.6 | 0.6 | 0.55 | |

| 0.2Mpa Refractoriness Under Load T0.6 ℃ | ≥1600 | ≥1600 | ≥1650 | |

| Thermal Shock Resistance 1000℃ water cycles | ≥18 | ≥18 | ≥18 | |

Mullite bricks are mainly used for top of hot blast stove, stack and bottom of blast furnace, regenerative chamber of glass melter, ceramic post sintering kiln, furnace lining for dead angle of petroleum cracking and etc.

Leave a message to get the price list for free